Fivetone Cabinetry

Bespoke Furniture

Individually designed, carefully handmade and expertly fitted

A personalised experience every step of the way

Chris is a cabinet and furniture maker based in Stroud, Gloucestershire, designing and hand-making both fitted and freestanding furniture.

Everything is made using high-quality materials, with the full process handled in-house — from design and manufacture through to finishing and fitting. That hands-on approach means every detail is considered and the finished piece is built to last.

Fivetone Cabinetry specialises in wardrobes, alcove units, kitchens, office furniture, bookcases and bespoke freestanding pieces.

Process

Personalised Design using SketchUp

At Fivetone Cabinetry, every project starts with a conversation. The aim is simple: to design furniture that fits your space properly and works the way you need it to.

I use SketchUp to design and develop each piece, which means you can see exactly how everything will look and function before anything is made. The 3D models make it easy to explore proportions, layouts and details, and to tweak things early on so there are no surprises later.

The design process begins with a detailed consultation, where we talk through your space, your requirements and how you want the furniture to be used. From there, the design is refined step by step, with clear visuals and honest input on what will work best.

Using SketchUp, I can walk you through the design from all angles, helping you understand how the piece will sit in the room and how it will function day to day. Any changes can be made at this stage, so the final design is properly resolved before it moves into the workshop.

Hand making in the workshop

Bespoke furniture is built properly when care is taken at every stage. At Fivetone Cabinetry, that means combining traditional joinery skills with modern machinery to get the best result, not just for how the furniture looks, but how it functions long term.

Each piece is made in the workshop with close attention to detail, from the way components are constructed through to how doors, drawers and moving parts operate. Nothing is rushed, and nothing is overcomplicated — the focus is on making furniture that works well and lasts.

Because everything is fully built and tested in the workshop, doors, drawers, shelves and hardware are properly fitted before installation. This keeps site work efficient and ensures the finished piece fits exactly as intended.

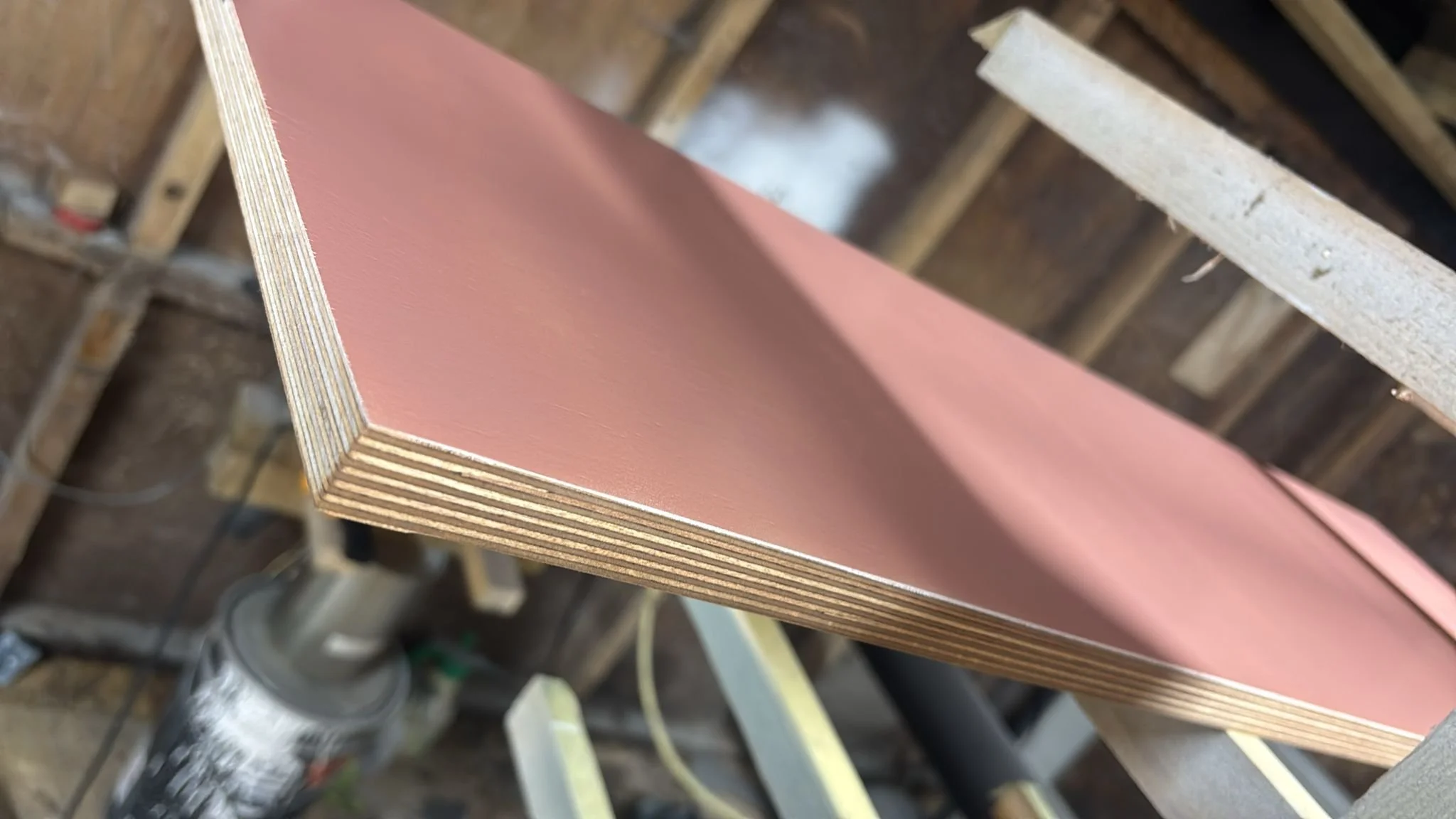

Finish

For painted and lacquered finishes, I work with local specialist sprayers RJ Hunt & Sons. Using a dedicated spray shop means the finish is consistent, durable and properly suited to furniture that’s built to be used every day.

This allows for a full range of finishes, including painted, lacquered, varnished and oiled surfaces. Paint can be matched to any colour, while clear finishes are chosen to suit the material and how the piece will be used.

By working closely with an experienced local sprayer, the final finish is as carefully considered as the furniture itself.

Fitting

The final stage of the process is delivery and installation. This is where the design, making and finishing come together, and the furniture is fitted properly into the space it was designed for.

With fitted furniture in particular, this is where everything clicks into place — the proportions, the detailing and how the piece relates to the room. The aim is always for the furniture to feel intentional: something that has a clear presence, but also looks as though it belongs there.

Careful installation ensures clean lines, accurate fitting and a finished result that feels considered and complete.

Book a Visit

Clear design, clear pricing, clear process.